Start with the purpose

Every fit-out should reflect the real work you do:

- Metro stop/slow and short shifts — speed and efficiency

- Arterial and motorway closures — visibility and endurance

- Mobile works and emergency response — mobility and uptime

Your configuration, equipment, and technology need to serve the 80% of your work — not the exceptions.

The right platform: payload, uptime, and serviceability

- Cab type: Single/Extra cab usually wins, enough space for gear without sacrificing tray length.

- Drivetrain: 4×2 for sealed roads; 4×4 for verges and access tracks.

- Payload: Target at least 800 kg after fit-out; plan for a GVM upgrade early if needed.

- Reliability: Choose a brand with strong service coverage, and resale value: HiLux, Ranger, D-MAX all fit the brief.

- Electrical headroom: Traffic equipment draws constant power. Run a dedicated dual-battery system independent of the vehicle’s starting battery, charged via a quality DC-DC charger from the alternator. This setup keeps lights, boards, and tech running without idling the engine, saving fuel and reducing wear.

Fit-out that earns, not costs

Safety and visibility

- LED Arrow Board built to AS standards.

- High-output scene lights with automatic dimming.

- Reflective chevrons, compliant decals, and correct height placement.

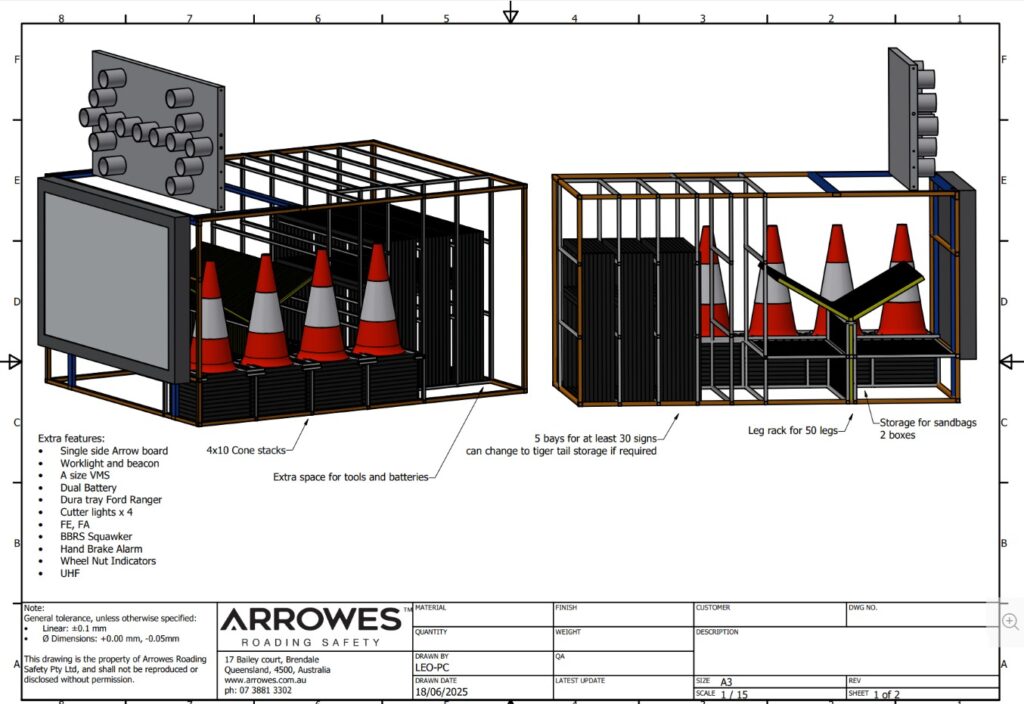

Traffic management gear

- Cone pod or slide-out cone bay (max 40 cones). Too many adds dead weight.

- Sign cages built to the worst-case regional height (NSW signs often differ).

- Secure storage for portable traffic lanterns (eSTOPs), include charging ports and cable routing so they’re ready every shift.

Power and wiring

- Lithium system with DC-DC charging and solar top-up.

- Separate circuits for “dirty” (lighting) and “clean” (electronics) power.

- Label every harness; provide diagrams and service loops.

Active safety systems

Modern vehicles now offer fatigue detection, lane departure warning, blind-spot radar, and collision avoidance. In a traffic management context, these can be literal lifesavers during long night shifts or high-risk closures.

Smart visibility: VMS and radar integration

For highway and motorway work, a Vehicle-Mounted Variable Message Sign (VMS) turns the ute into a dynamic warning system.

Integrate radar technology to measure approach speed and change the displayed message in real time — “SLOW DOWN 78 km/h” instead of a static warning.

This not only modifies driver behaviour but provides post-job insight through captured data:

- Average and peak approach speeds

- Frequency of speeding incidents

- Time-of-day trends

This information can be shared with clients and authorities to justify risk controls and prove safety performance.

Telemetry and IoT, your invisible workforce

The right telemetry is the backbone of any modern fleet. It’s no longer just about GPS dots on a map.

A complete IoT-ready vehicle collects and transmits:

- Location and idle time for asset utilisation

- Event footage from DVR systems

- Speeding and near-miss data from radar sensors

- Battery and power diagnostics from eSTOPs or other devices

- On-site event logs into cloud systems like ASIST

This data enables data-driven decision-making, incident reconstruction, and targeted safety improvements — something a basic ute simply can’t do.

Build quality matters, pick the right manufacturer and installer

Every good fit-out starts with a builder who understands traffic management. Look for:

- Proven experience with TTM specs and Chain of Responsibility obligations

- Clean wiring and documentation

- Use of Australian-made or certified components

- Willingness to innovate, not copy. Continously improve!

- Proper tray load distribution and certified GVM calculations

The wrong fabricator will cost you more in downtime and retrofits than the cheapest quote ever saved.

ROI: How a well-built ute pays for itself

- Faster setup and pack-down: Smarter layout and lighting save 10–20 minutes per shift, around $5,000–$6,000 a year in labour efficiency.

- Less downtime: Reliable electrics and organised storage prevent costly faults and call-outs. One avoided lost day can cover most of the fit-out cost.

- Lower fuel use: Dual-battery systems remove unnecessary idling, saving 400–800 litres of diesel a year and reducing wear.

- Reduced risk: Better ergonomics, lighting, and fatigue detection lower the chance of injury or near-miss events.

- Data advantage: IoT and radar capture help prove compliance, improve safety reports, and strengthen bids for future work.

Most operators recover their investment in 18–24 months, with ongoing savings year after year.

What the “new” traffic control vehicle looks like

It’s lighter, smarter, and connected:

- Data-ready and automation-ready (ASIST, eSERIES integration)

- Equipped with radar and IoT sensors

- Built for ergonomic and electrical efficiency

- Records and transmits what happens in the field

- Designed for modular upgrades — not a one-off custom job

- Alternative material – not just metal! Watch this space

Final take

Build your next traffic control vehicle like a business tool, not a capital expense.

Every cable, cone pod, and radar sensor should earn its place.

Work with a manufacturer who understands your region’s specs, invests in innovation, and can support your uptime.

Smart, safe, and connected — that’s what the modern traffic control ute looks like.

Keywords: Traffic control vehicle fit-out, traffic management ute, portable traffic light storage, eSTOP charging, vehicle-mounted VMS, radar speed display, IoT for road safety, ASIST system, telematics for traffic management, DC-DC charger, dual battery system, automation-ready fleet, roadworker safety technology, Arrowes Roading Safety, Australian-made traffic control equipment

Author: Nathan Psaila – General Manager of ARROWES Roading Safety